New wind power forecast integrated into ISO-NE processes and control room operations

More precise information about the predicted electricity output from wind resources improves dispatch efficiency, helps optimize power output from wind generators

More precise information about the predicted electricity output from wind resources improves dispatch efficiency, helps optimize power output from wind generators

Over the past several years, the amount of wind power connected to the New England high-voltage power grid has increased at a fairly quick pace—from approximately two megawatts (MW) in 2005 to more than 700 MW on the system today. Another 2,000 MW of wind generation has been proposed in the region.

The ISO has been taking steps to prepare for managing the grid with an increasing amount of this resource, which has operating characteristics different from traditional resources in that the fuel—wind—is variable. Recently, the ISO implemented a centralized wind power forecast for use in daily system operations, a major initiative under development since 2010 and a key recommendation from the New England Wind Integration Study (NEWIS). The new wind power forecasting tool allows for better utilization of power from wind resources and improves dispatch efficiency and system reliability.

Balancing the system with increasing amounts of wind

On today’s grid, electricity cannot be stored in large amounts—it has to be produced at the exact moment it is consumed and ISO system operators must manage and protect this careful balance. ISO load forecasters project consumer demand for power for seven days, the next day, and on an hourly basis, and those forecasts are adjusted in real time as needed. Accurate demand forecasts are critical to scheduling generators to produce the right amount of power every second of every day.

On today’s grid, electricity cannot be stored in large amounts—it has to be produced at the exact moment it is consumed and ISO system operators must manage and protect this careful balance. ISO load forecasters project consumer demand for power for seven days, the next day, and on an hourly basis, and those forecasts are adjusted in real time as needed. Accurate demand forecasts are critical to scheduling generators to produce the right amount of power every second of every day.

The variable power output from wind resources has an effect on power grid operations and, at times, can create challenges in maintaining system stability. For example, if a wind resource is supplying 50 MWs to the system at a given time, it offsets the need for another type of generator to be running. But the output from the wind generator can change quickly if the wind picks up speed or stops blowing. This variability in output means that other, flexible resources are needed to be able to quickly ramp up or down to help make up for the change. As more wind resources are interconnected to the grid, the operational complexity becomes more pronounced.

In 2010, the ISO completed NEWIS, a major study of the potential impacts of integrating large amounts of wind resources into the New England system. The study analyzed various planning, operating, and market aspects of wind integration. One of the key findings was that the successful integration of wind resources requires accurate, detailed wind power forecasts.

Wind power forecast: years in the making

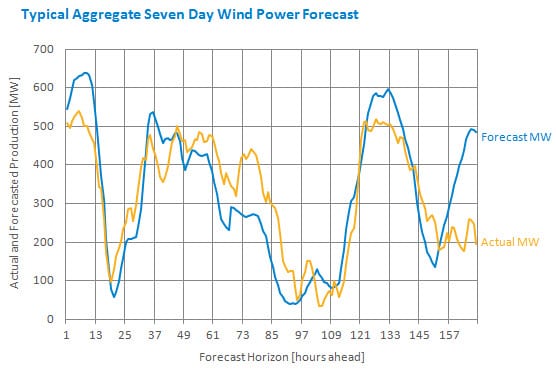

Over the course of the last few years, the ISO, in conjunction with its wind power forecasting contractor, Garrad Hassan, and energy management system vendor, Alstom, created a computer-based tool for forecasting wind more precisely. Three different forecasts are now incorporated into control room scheduling and dispatch services:

- Short term: wind power forecast for the next four hours, data updated every five minutes

- Intermediate term: wind power forecast for the next 48 hours, data updated every three hours

- Long term: wind power forecast for the next week, data updated every day

The implementation of these forecasts was the result of significant ISO and stakeholder collaboration. All 15 of New England’s large wind plants (ranging in size from 10 MW to 130 MW), totaling about 710 MW, now send meteorological data such as wind speed, direction, and air temperature, collected by sensors at their facilities, to the ISO. These data are combined with information from other weather services in a high-performance-computing simulator that ultimately produces the wind power forecasts.

Forecasts incorporated into ISO processes, system operations

The forecasts are already providing benefits to the New England grid in several important ways.

More efficient dispatch of the system

With the forecast in place, ISO system operators now have access to detailed information, in advance, about where, when, and approximately how much electricity will be produced by each large wind plant in New England. This in turn helps operators more efficiently commit resources to meet demand. More specifically, it allows operators to have greater confidence in the amount of electricity each wind facility will likely be able to generate at a given time, which will decrease the need to commit more generation from other types of power plants. This should also help limit the number of times when there is not enough generation available and ready to produce electricity when wind speed, and, therefore, wind energy output, is lower than the wind plant offered to provide.

The ISO’s short-term outage coordination department is also using the long-term (seven day) wind forecast to help schedule generator and transmission outages.

Greater situational awareness

A new control room display depicting both forecasted and actual real-time wind data improves control room operators’ situational awareness. The forecasting tool also enhances the ISO’s ability to prepare for wind-ramp events that can occur when storms or other high-wind events are predicted. These events can push wind turbines into “overspeed” and cause them to trip them offline suddenly, which can negatively impact system reliability.

Fewer Min Gen events and curtailments

The forecasting tool has already resulted in fewer orders to wind plants to curtail their output under certain circumstances. With more efficient dispatch of the system, the amount of Minimum Generation (Min Gen) events (when the amount of generation is close to exceeding the demand for electricity) is reduced, resulting in fewer wind curtailments. Further, the improved information has allowed the ISO to update its operating procedure related to Min Gen events. Previously, prior to the declaration of a Min Gen Emergency, a number of steps—including the curtailment of resources, such as wind—would take place. With the more precise information about output from wind facilities, the need to reduce generation prior to a Min Gen Emergency has been removed, further reducing the amount of wind curtailments under these system conditions.

The ISO has made this forecasting data available to each of the large wind plants in New England (each participant is allowed to view only the forecast for their own facility) and, as resource owners gain more experience with the forecast, they may be able to participate in the Day-Ahead Energy Market more effectively, which should reduce the curtailment of wind plants to ensure reliability. Resources that clear in the day-ahead market are committed to provide power during the operating day. Up to now, wind plants typically have not offered into the day-ahead market to get a commitment to provide a certain amount of power the following day, due to uncertainty about how much power they will be able to produce. With the greater certainty this forecast provides, more wind plants may use this information to submit an offer into the day-ahead market to produce a certain amount of electric energy in the operating day. Should the need for curtailment of generation arise due to transmission constraints or other system reliability-related issues, resources without day-ahead commitments are curtailed before resources with commitments.

Going forward

The growth of wind resources adds diversity to the region’s generation portfolio and can also help meet the states’ renewable energy goals. Incorporating low-fuel-cost generation into the system, such as wind, in an efficient manner may also help lower wholesale energy clearing prices by displacing other resources with higher fuel costs. At the same time, the growth of wind power is adding new and complex challenges to managing the New England power grid. The addition of the wind power forecasting service will help the region maximize the use of power from wind resources while also helping maintain system reliability.

The growth of wind resources adds diversity to the region’s generation portfolio and can also help meet the states’ renewable energy goals. Incorporating low-fuel-cost generation into the system, such as wind, in an efficient manner may also help lower wholesale energy clearing prices by displacing other resources with higher fuel costs. At the same time, the growth of wind power is adding new and complex challenges to managing the New England power grid. The addition of the wind power forecasting service will help the region maximize the use of power from wind resources while also helping maintain system reliability.

- Categories

- Inside ISO New England

- Tags

- forecast, renewable resources, system operations, wind